CNC Custom Machining Empowers Innovation in Bioreactors, Sensors, and Detection Instruments

With the advancement of technology and industrial development, products such as bioreactors, sensors, and detection instruments are playing an increasingly important role in fields such as healthcare, life sciences, and environmental monitoring. Behind these highly precise and demanding devices lies the support and driving force of CNC custom machining. This article will explore the applications of CNC custom machining in the fields of bioreactors, sensors, and detection instruments, as well as its importance in driving innovation in these areas.

I. Application of CNC Custom Machining in Bioreactor Manufacturing

Bioreactors are devices used for cultivating cells, microorganisms, or biological enzymes and are widely used in biopharmaceuticals, bioengineering, and life science research. CNC custom machining can precisely fabricate various shapes and materials of bioreactor components according to customer requirements, ensuring the stability, precision, and reliability of the equipment. For example, CNC machining technology can be utilized to manufacture high-precision reactor vessels, agitators, and temperature control devices to meet the needs of different experimental conditions.

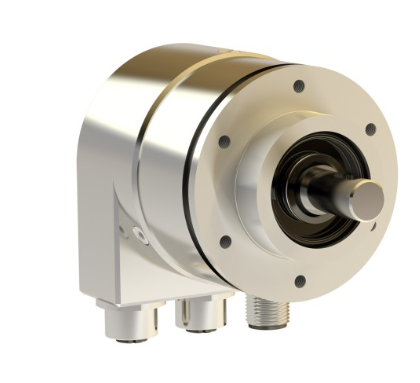

2. Application of CNC Custom Machining in Sensor Manufacturing

Sensors play a crucial role in industrial control, medical diagnosis, environmental monitoring, and other fields, with their performance and accuracy often depending on manufacturing processes and material selection. CNC custom machining can precisely fabricate the tiny components required for sensors, such as sensing elements, connectors, and housings, ensuring the sensitivity, stability, and durability of the sensors. For instance, CNC machining can be used to produce high-precision parts for pressure sensors, applied in medical equipment or industrial automation systems, achieving precise monitoring and control of pressure changes.

3. Application of CNC Custom Machining in Detection Instrument Manufacturing

Detection instruments are widely used in medical diagnosis, environmental monitoring, food safety, and other fields, with their accuracy and reliability being crucial for data accuracy. CNC custom machining can fabricate various precision components for detection instruments according to design requirements, such as optical components, sensor brackets, and fluid control valves, enhancing the performance and stability of detection instruments. For example, in spectrometer manufacturing, CNC machining can achieve high-precision machining of optical components, ensuring the accuracy and reliability of spectral analysis.

In conclusion, CNC custom machining plays a crucial role in the fields of bioreactors, sensors, and detection instruments, providing key support for the innovative development of these products. With continuous advancements in technology and processes, CNC custom machining will continue to drive innovation in areas such as biomedical and environmental monitoring, making greater contributions to human health and environmental protection.

Contact Us

Request A Quote